| Department | Materials Physics |

|---|---|

| Research group | |

| Qualifications | PhD |

| Office phone | (02) 612 56361 |

| Skype | mohammad.saadatfar |

| Office | Cockcroft 4 56 |

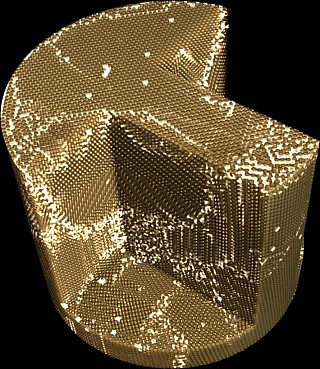

3D visualisation of a partially crystallised packing containing 200000 beads. Bright regions indicate the location of disordered aggregates of beads, which are placed at the boundaries of ordered domains.

3D visualisation of a partially crystallised packing containing 200000 beads. Bright regions indicate the location of disordered aggregates of beads, which are placed at the boundaries of ordered domains. Have you ever wondered why we only leave footprints on wet beaches not on dry sand? Or why wet sand looks dry the moment you stand on it? Or have you thought about landslides and what triggers them? Or how a large assembly of cells can pile up and form a living tissue? Answering these simple questions requires a deep understanding of the kinematics and mechanics of granular materials. There have been many developments in understanding the nature of granular materials in recent years, but to date some questions are still topics for debate; questions such as the dynamics of the interaction between individual grains and the distribution of forces inside granular packings.

At the Department of Applied Mathematics at ANU, we have the necessary experimental aparatus and computing power combined with years of research experience in the field of granular materials to address some of the fundamental questions in this area. Students involved in this project will learn to design and perform experiments to understand the nature of forces in granular materials. Parallel to the experiments, students will learn common numerical techniques such as Molecular Dynamics and the Discrete Element Method to simulate packings of granular materials. These simulations will give us the flexibility of performing virtual experiments with controlled parameters to compare with real experiments and therefore validate the results.

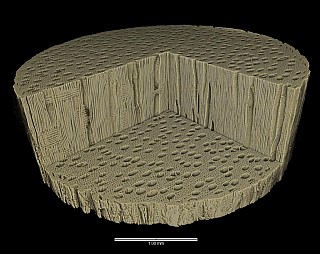

Microstructure of willow obtained by ANU's micro-CT facility. The fibres and capillaries are clearly visible at micron scale.

Microstructure of willow obtained by ANU's micro-CT facility. The fibres and capillaries are clearly visible at micron scale.English willow and Kashmir willow dominate the global market for cricket bats. Cricket bats made of English willow are said to the best. In this project we aim to find out why the English willow (salix alba var.caerulea) is the superior raw material to manufacture the first-class, test grade cricket bats.

The project employs a wide range of tools including micro-CT imaging technology and related analysing tools to investigate the unique properties of wood at the cellular scale.

A long term goal of this project is the identification of potential wood candidates to match the structural and mechanical properties possessed by the English willow.

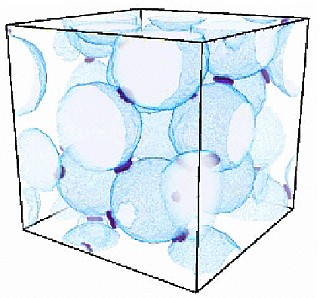

The contact zone between grains (dark patches) provides a measurement of contact forces. This image was acquired at ANU's micro-CT facility.

The contact zone between grains (dark patches) provides a measurement of contact forces. This image was acquired at ANU's micro-CT facility. Heinrich Rudolf Hertz, the great 19th century German physicist, worked out how two symmetric objects will behave under loading when placed in contact. Hertz summarised his research on contact mechanics in two important papers published between 1886-1889 which are amongst the most cited references in the field of solid mechanics and granular dynamics today. While Hertz's work was a first class pioneering research at the time, he nevertheless didn't address the complexity that arises when more than two axi-symmetric objects are in contact. This is especially important in understanding the mechanical stability of large assemblies of granulated systems. A detailed knowledge on the mechanics of such systems will help predict often catastrophic geological phenomena such as avalanches and slurries.

In this project, students will attempt to expand Hertz's original idea to include multiple solids as well as to understand the effect of adhesion in contact dynamics. During the course of this project, students will gain valuable experience working in a friendly and scientifically diverse environment while learning to use advanced equipment.

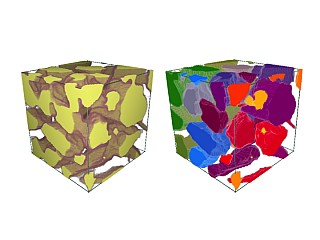

Segmentation of a 3D image of a sandstone rock (left) into a 3D binary image where each grain has been identified (right)

Segmentation of a 3D image of a sandstone rock (left) into a 3D binary image where each grain has been identified (right)Using Artificial Intelligence (AI) for image classification and object recognition is not new. Many techniques and sophisticated software have been developed over the past decade to do just that. Extending some of the well established machine learning techniques to three dimensional images such as those made by micro-CT is a new challenge.

Image classification may be performed using supervised, unsupervised or semi-supervised learning techniques. In supervised learning, the system is presented with numerous examples of images that must be manually processed and labeled. Using this training data, a learned model is then generated and used to predict the features of unknown images.

Over the past 15 years, the X-ray CT machines at the Department of Applied Mathematics have been busy producing thousands of 3D images. A 3D image may be composed of multiple elements, minerals, alloys etc. Separating these components can be challenging and is certainly a laborious manual task in 3D.

In this project, the students will be working closely with the researchers to implement machine-learning techniques for material identification in 3D images.